OEM/ODM Factory Rubber Hose Tube - FKM/ECO 4 Layers Reinforced SAE J30R9 Automotive Fuel Injection Fuel Supply System Fuel Hose – JINBEIDE

OEM/ODM Factory Rubber Hose Tube - FKM/ECO 4 Layers Reinforced SAE J30R9 Automotive Fuel Injection Fuel Supply System Fuel Hose – JINBEIDE Detail:

| Product: | FKM/ECO 4 Layers Reinforced SAE J30R9 Automotive Fuel Injection Fuel Supply System Fuel Hose |

| Item No.: | JBD-E018 |

| Size & Shape: | ID≥Φ2.5 mm; Customized as Required. |

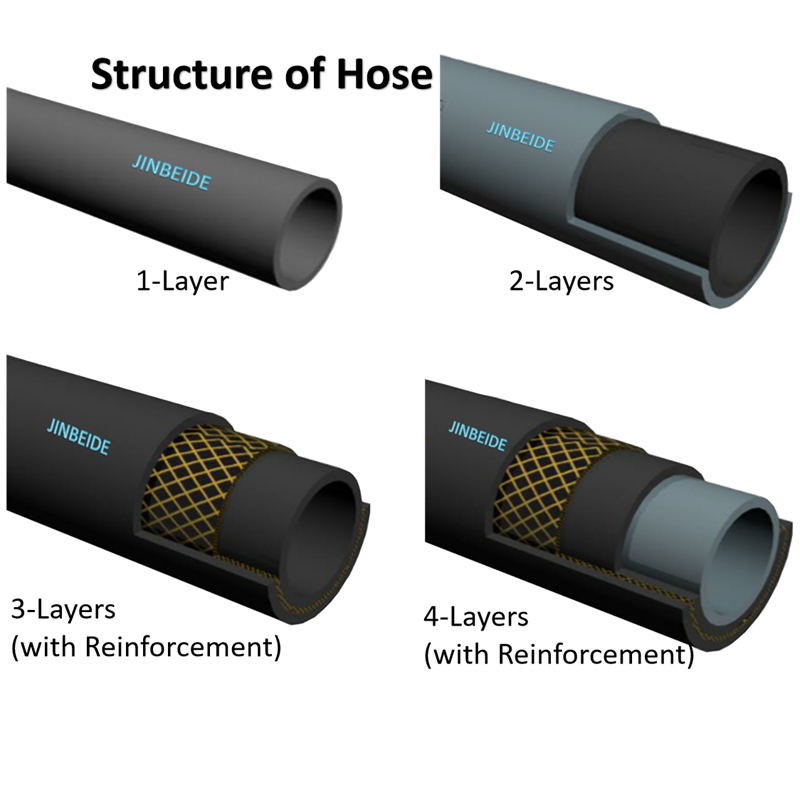

| Material: | FKM/ECO/YARN/ECO |

| Color: | Black |

| Application | Use for Fuel Injection /Fuel Supply system in Automobiles, Motorcycles.ATV,Garden Machinery,Engines,Generators and so on |

| Standard | SAE, YDK,HES, EX-S,ASTM and so on |

| Shipping Port | Xiamen |

| OEM/ODM | Accepted |

| Package | PE bag+Carton+Pallet |

| Payment Terms | T/T, L/C,Western Union |

| Factory | ISO/IATF16949 registered |

| Technical Teams | 30+ Years experience |

| Sample Leadtime | 7-15 days |

| Production Leadtime | 20-30 days |

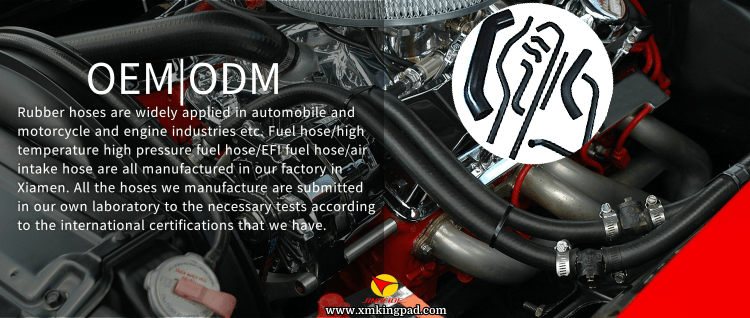

OEM & ODM

FKM/ECO 4 Layers Reinforced Automotive Fuel Injection Fuel Supply System Fuel Tank Inlet Hose can be accepted OEM & OEM as per client’s drawings ,samples and other specifications,are widely applied in automobile and motocycle and engine industries ect, Fuel Hose, High Temperature & High Pressure Fuel Hose, EFI Fuel Hose, Air Intake Hose are all manufactured in our factory. All the hoses we manufactured are submitted in our laboratory to the necessary tests and meet the Standard of SAE, YDK,HES, EX-S,ASTM and so on,

The Main materials are FKM/ECO; FKM/ECO/YARN/ECO; ACM/YARN/ACM;NBR/YARN/CSM;NBR/YARN/NBR+PVC;NBR+PVC;NBR+CSM/CM;

NBR,NR,ECO,ECO/CSM. and so on.

SPECIFICATION

| Test Condition and Result | ||||||||||

| NO | Item | Test Condition | Basic Value | Test Value | Judge | |||||

| 1 | Burst test | Test burst pressure | ≥6.2MPa | 7MPa | OK | |||||

| 2 | Vacuum Collapse Test | 一81KPa ,15-60 seconds | OD Changing Rate,Max:-20% | -6.5% | OK | |||||

| 3 | Col Flexibility | A)、To be dry heat aged for 135℃×70Hrs,after aging,to be conditioned at -40℃×5Hrs | Fixed in the cold chamber through 180 degrees from the the centerline to a diameter of 10 times the Max OD of the hose | NOT FRACTURE, NO CRACKS, NOCHEKS, NO BREAKS |

OK | |||||

| Burst pressure ≥0.69MPa | 0.81MPa | OK | ||||||||

| B)、To be immersed in ASTM Oil No. 3 for 135℃×70H,then to be conditioned at -40℃×5Hrs | Fixed in the cold chamber through 180 degrees from the the centerline to a diameter of 10 times the Max OD of the hose | NOT FRACTURE, NO CRACKS, NOCHEKS, NO BREAKS |

OK | |||||||

| Burst pressure≥0.69MPa | 0.76MPa | OK | ||||||||

| 4 | Tensile Strength | Outer Layer ≥8MPa Midium/Inner Layer ≥5MPa |

Outer:10MPa Midium:10MPa Inner:9MPa |

OK | ||||||

| Elongation | Outer Layer ≥150% Mid/Inner Layer ≥125% |

Outer:259% Midium:296% Inner:276% |

OK | |||||||

| 5 | Dry Heat Resistance | Ater 150℃*7days being aged, Slowly straighten | Surface without cracking and carbonization | No cracking and carbonization | OK | |||||

| 6 | FUEL RESISTANCE | To be immersed in FUEL C RT*48Hr | Inner Layer:rate of volume change ≤+10% | 7% | OK | |||||

| 7 | OIL RESISTANCE | 试To be immersed in ASTM Oil 3#150℃*7Hrs | Outer Layer:Change rate of tensile strength ≤+100% | 55% | OK | |||||

| 9 | OZONE RESISTANCE | SHALL BE ACCORDANCE WITH ASTM D 1149, THE SPECIMEN SHALL BE ALLOWED TO REST IN AN OZONE-FREE FOR 23℃×24H ,AND THE MOUNTED SPECIMEN SHALL BE PLACED IN A TEST CHAMBER CONTAINING OZONE AT 100MPA×40℃,AFTER 70Hrs OF EXPOSURE | NO CRACKS (BE VISUALLY INSPECTED UNDER 7X MAGNIFICATION) |

No Cracks | OK | |||||

| 10 | ADHESION | Length 25.4mm | peel strength ≥35.6N | 75N | OK | |||||

| 11 | KINK RESISTANCE | 300MM LONG SPECIMEN,23℃×2H,BEND HOSE ALONG ITS NATURAL CURVATURE AND INSERT THE OTHER END CAREFULLY INTO THE SECOND HOLE UNTIL IT PROJECTS 63 MM OUT THE OTHER SIDE | The ball is free to pass through | The ball is free to pass through | OK | |||||

| 12 | Ethanol fuel resistance test | To be immersed in 85%FUEL D+15% absolute ethyl alcohol RT *70Hr | Inner Layer: change rate of tensile strengthMax -40% ; | -20% | OK | |||||

| Inner Layer:Change rate in elongation:Max -40%; | -28% | OK | ||||||||

| Inner Layer:Chang rate of Volume: Max 0-15% | 7% | OK | ||||||||

| 13 | OXIDIZED FUEL TEST | —Cut three tensile (D471 C#) specimens to immerse in 200ml mixture consisting of 3600 mL of ASTM Fuel “B” and 10 mL of 90% t-butyl hydroperoxide for 40℃*14 days | Inner Layer: change rate of tensile strengthMax -30% ; | -15% | OK | |||||

| Inner Layer:Change rate in elongation:Max -20%; | -12% | OK | ||||||||

| 14 | Low Permeation test | ASTM FULE C, METHODS CONFORM TO 9.1~9.2 and EPA Regulation |

≤15g/m2/day | 10.2 | OK | |||||

APPLICATION

FKM/ECO 4 Layers Reinforced Automotive Fuel Injection Fuel Supply System Fuel Tank Inlet Hose widely Use for Fuel Supply System, Transmission System, Power Steering System, Brake System, Air Intake system in Automobiles, Motorcycles, ATV, Garden Machinery, Engines, Generators and so on.

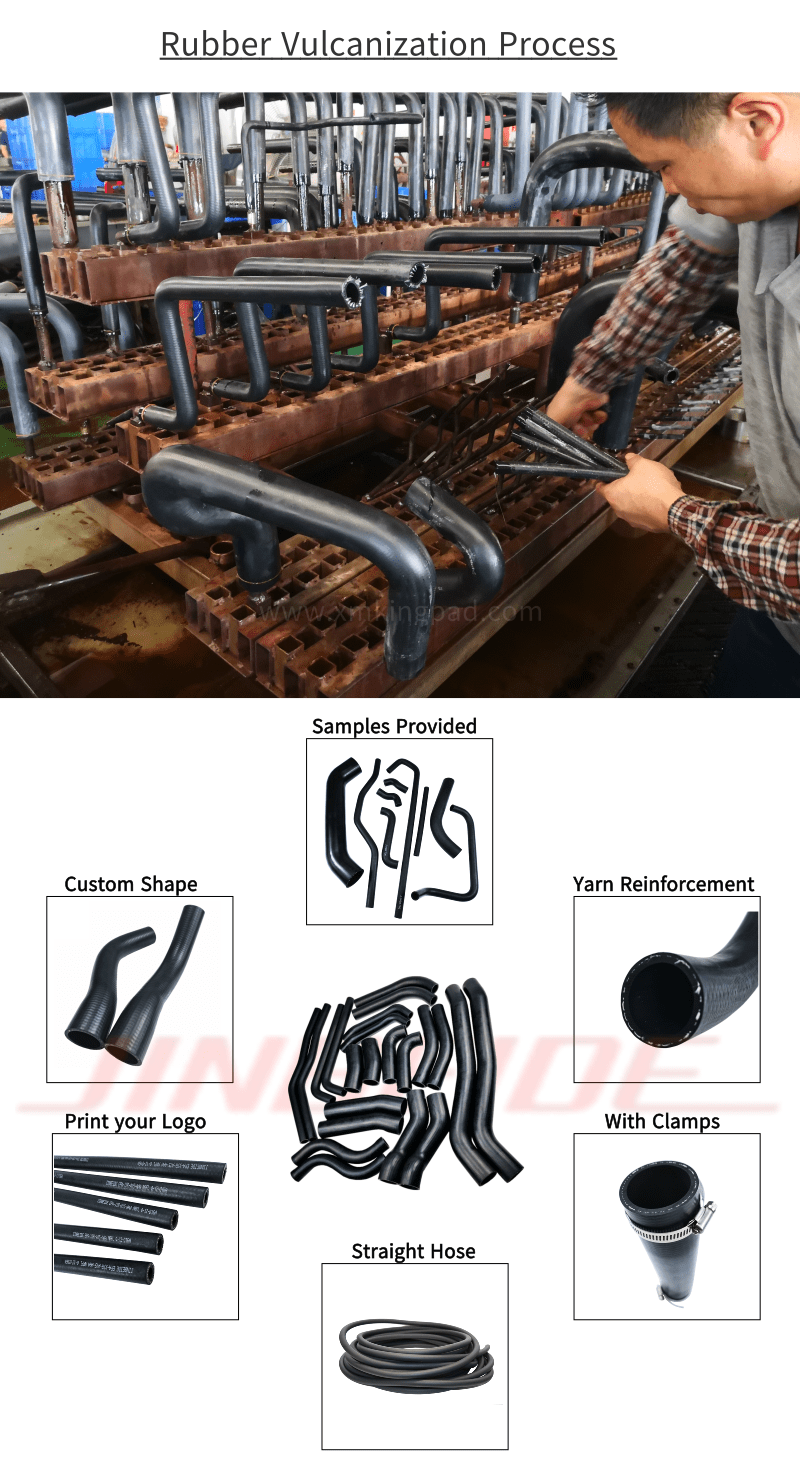

Product detail pictures:

Related Product Guide:

Our goal is to provide high quality products at competitive prices, and top-notch service to customers around the world. We are ISO9001, CE, and GS certified and strictly adhere to their quality specifications for OEM/ODM Factory Rubber Hose Tube - FKM/ECO 4 Layers Reinforced SAE J30R9 Automotive Fuel Injection Fuel Supply System Fuel Hose – JINBEIDE , The product will supply to all over the world, such as: Serbia, Singapore, Pakistan, As operation principle is "be market-oriented , good faith as principle, win-win as objective", holding on "customer first, quality assurance, service first" as our purpose, dedicated to provide the original quality, create excellence service , we won the praise and trust in the industry of auto parts. In the future, We will provide quality product and excellent service in return to our customers , welcome any suggestions and feedback from all over the world.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.