Personlized Products Ethanol Resistant Fuel Hose - EPA & Carb Compliant Electronic Fuel Injection (EFI) Hose Rubber Fuel Line – JINBEIDE

Personlized Products Ethanol Resistant Fuel Hose - EPA & Carb Compliant Electronic Fuel Injection (EFI) Hose Rubber Fuel Line – JINBEIDE Detail:

| Product: | EPA & Carb Compliant Electronic Fuel Injection (EFI) Hose Rubber Fuel Line |

| Item No.: | JBD-C002 |

| Size & Shape: | ID≥Φ2.5 mm; Customized as Required. |

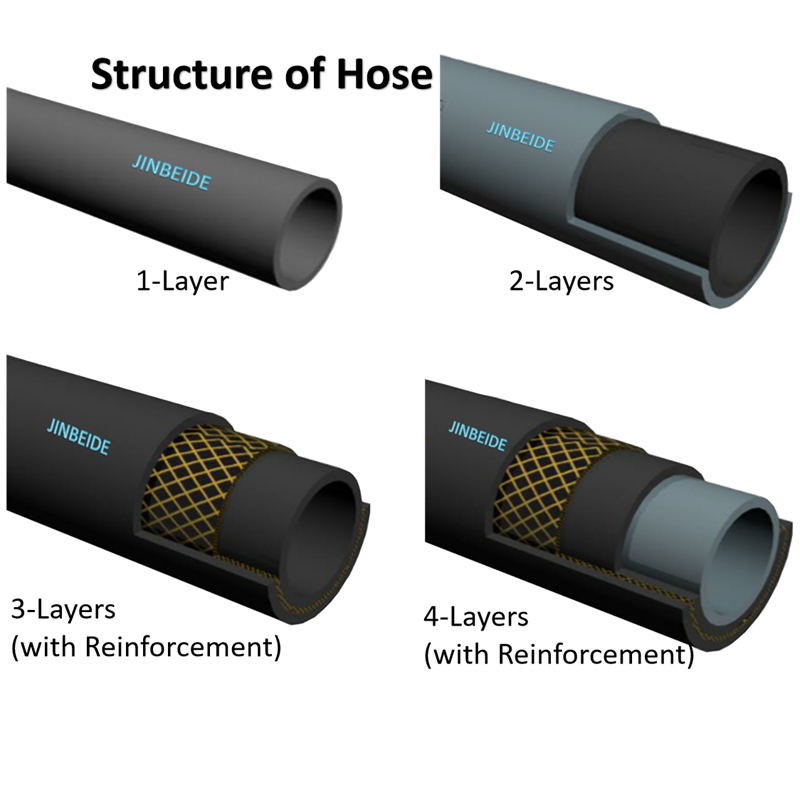

| Material: | FKM/ECO/AR/ECO |

| Structure: | Four layers |

| Color: | Black |

| Application | Use for Electronic Fuel Injection(EFI) in Engines in Automobiles,Motorcycles,ATV,UTV,Garden Machinery,Outdoor Power Equipments,and so on. |

| EPA & CARB CERTIFICATE | YES. |

| Standard | SAE, YDK,HES, EX-S,ASTM and so on |

| Shipping Port | Xiamen |

| OEM/ODM | Accepted |

| Package | PE bag+Carton+Pallet |

| Payment Terms | T/T, L/C,Western Union |

| Factory | ISO/IATF16949 registered |

| Technical Teams | 30+ Years experience |

| Sample Leadtime | 7-15 days |

| Production Leadtime | 20-30 days |

RUBBER TEST METHODS & SPECIFICATIONS

| RUBBER TEST METHODS & SPECIFICATIONS | Unit | Value | |||

| EXTRACTABLES | ASTM FULE C,300MM LONG SPECIMENS METHODS CONFORM TO 6.5.8 |

g/m2 | 2.50 MAX | ||

| PERMEATION | ASTM FULE C, METHODS CONFORM TO 9.1~9.2 |

g/m2/24H | 15 MAX | ||

| BURST | HOSE ID < 9.53mm | MPA | 6.2 MIN | ||

| HOSE ID > 9.53mm | MPA | 3.4 MIN | |||

| VACUUM COLLAPSE | DURING APPLICATION OF VACUUM FOR A MINIMUM OF 15S AND NOT MORE THAN 60S | % | 20 MAX | ||

| COLD FLEXIBILITY | TO BE DRY HEAT AGED FOR 135℃×70H,AFTER AGING,TO BE CONDITIONED AT -34℃×5H,THEN FLEXED IN THE COLD CHAMBER THROUGH 180 DEGREES FROM THE CNETERLINE TO A DIAMETER OF 10 TIMES THE MAXIMUM OD OF THE HOSE | NOT FRACTURE, NO CRACKS, NOCHEKS, NO BREAKS |

|||

| OZONE RESISTANCE | SHALL BE ACCORDANCE WITH ASTM D 1149, THE SPECIMEN SHALL BE ALLOWED TO REST IN AN OZONE-FREE FOR 23℃×24H ,AND THE MOUNTED SPECIMEN SHALL BE PLACED IN A TEST CHAMBER CONTAINING OZONE AT 100MPA×40℃,AFTER 70H OF EXPOSURE | NO CRACKS (BE VISUALLY INSPECTED UNDER 7X MAGNIFICATION) |

|||

| ADHESION | SEPARATE A 25.4MM WIDTH | N | 35.6 MIN | ||

| KINK RESISTANCE | 300MM LONG SPECIMEN,23℃×2H,BEND HOSE ALONG ITS NATURAL CURVATURE AND INSERT THE OTHER END CAREFULLY INTO THE SECOND HOLE UNTIL IT PROJECTS 63 MM OUT THE OTHER SIDE | PASS | |||

| DRY HEAT RESISTANCE | THE HOSE TO SLOWLY STRAIGHTENED(TAKING 7 TO 8S)AFTER BEING EXPOSED AS SHOWN IN FIGURE FOR A PERIOD OF 7 DAYS FOR 150 ℃ | NO CRACKS, NO CHARRING, NO DISINTEGRATION |

|||

OEM & ODM

EPA & Carb Compliant Electronic Fuel Injection (EFI) Hose Rubber Fuel Line can be OEM & OEM as per client’s drawings ,samples and other requirements, meeting the Low Permeation requirement according to the Standard of SAE, YDK,HES, EX-S,ASTM.

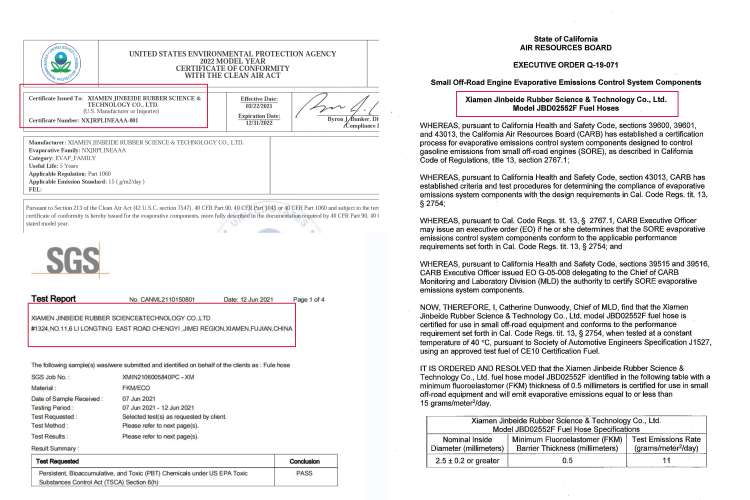

EPA & CARB CERTIFICATE

EPA & Carb Compliant Electronic Fuel Injection (EFI) Hose Rubber Fuel Line is achieved the EPA & CARB Certificate in North American, meeting the Low Permeation at Max 15 g/m2/day requirements of SAE J30.

Application

EPA & Carb Compliant Electronic Fuel Injection (EFI) Hose Rubber Fuel Line is use for Electronic Fuel Injection(EFI) in Engines in Automobiles,Motorcycles,ATVs,UTV,Garden Machinery,Outdoor Power Equipments,and so on.

Our Uniquie Advantages:

A: 30+ Years Experienced Professional Technical Teams with strong R&D Center.

B: Powerful Capacity with 4 Factories Production Base.

C: Stable Quality and Competitive Price—-We are an integrated company combining Rubber Raw Materials Refining & Mixer Process and manufacturing Rubber products with professional Technics, as well as Rubber Raw Materials Wholesales.

D: Delivery time—-20-30 days for mass production.

Structure of Hose

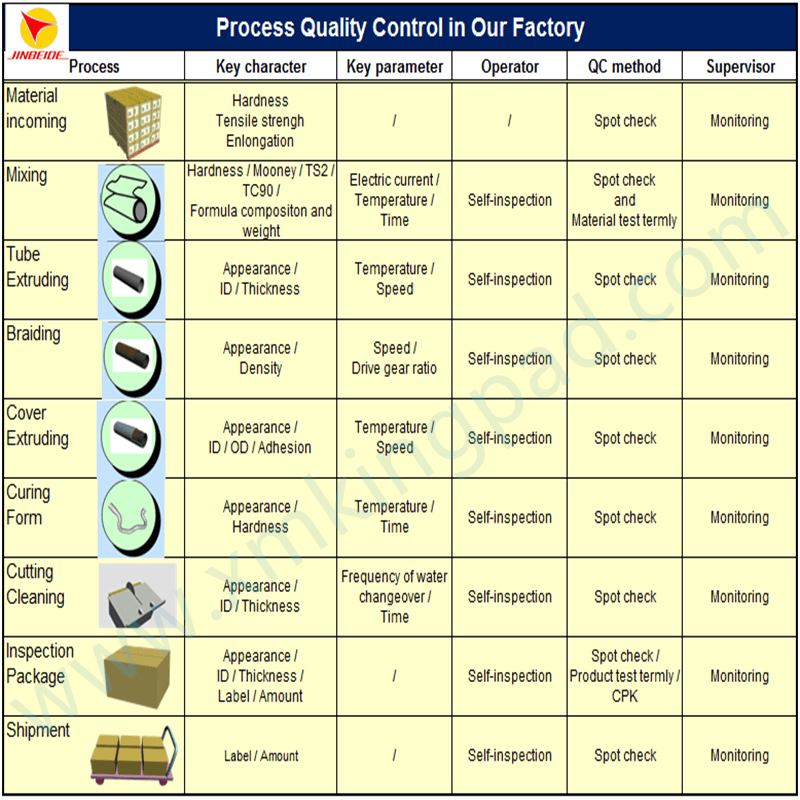

Process Of Quality Control

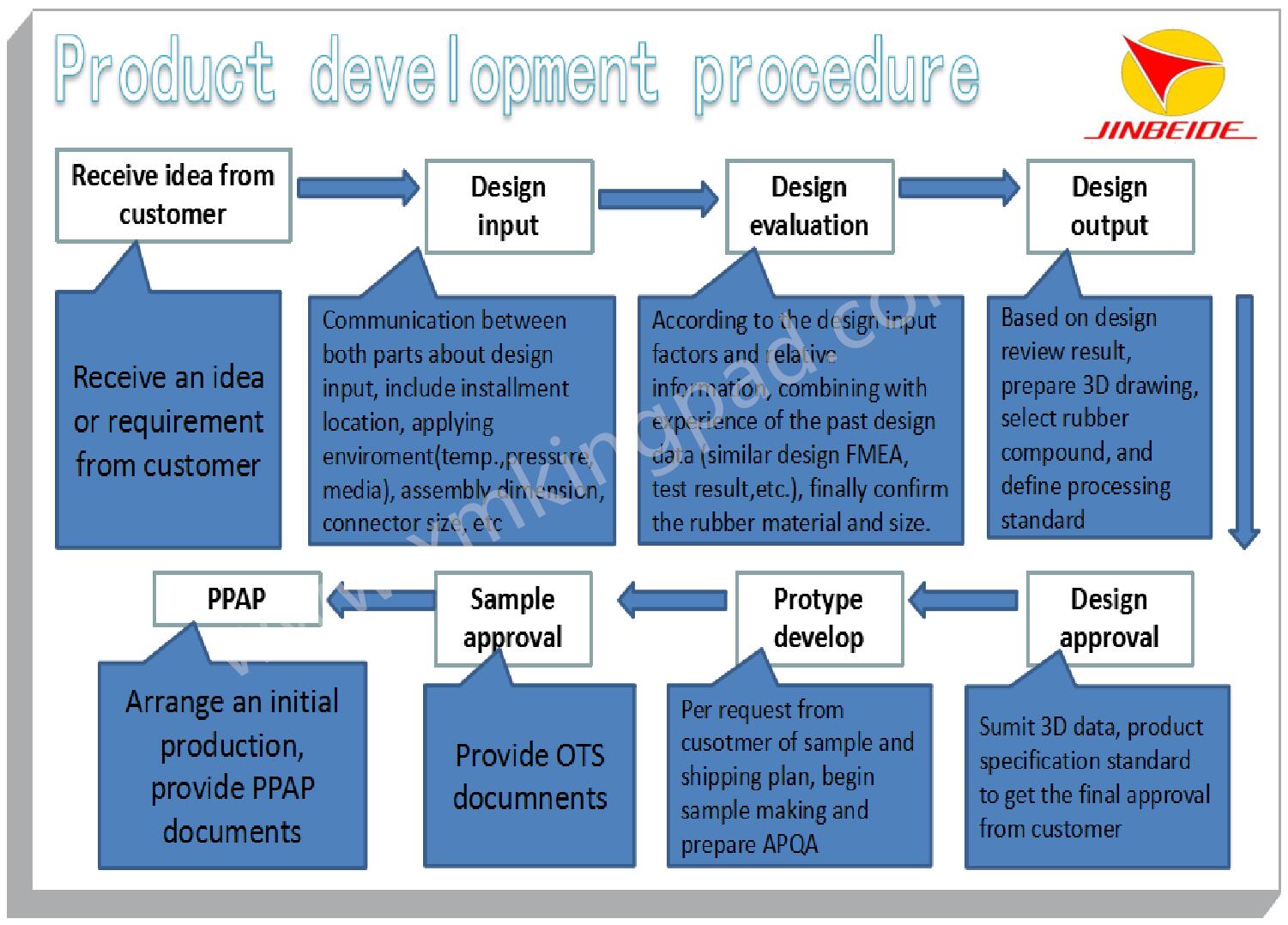

Process of Product Development

Products Collect

Packaging & Shipping

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Personlized Products Ethanol Resistant Fuel Hose - EPA & Carb Compliant Electronic Fuel Injection (EFI) Hose Rubber Fuel Line – JINBEIDE , The product will supply to all over the world, such as: Czech, Stuttgart, Lisbon, we have complete material production line, assembling line , quality control system, and the most importantly, we have many patents technology and experienced technical&production team, professional sales service team. With all those advantages, we are going to create"the reputable international brand of nylon monofilaments", and spreading our products to every corner of the world. We are keep moving and try our best to serve our customers.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.