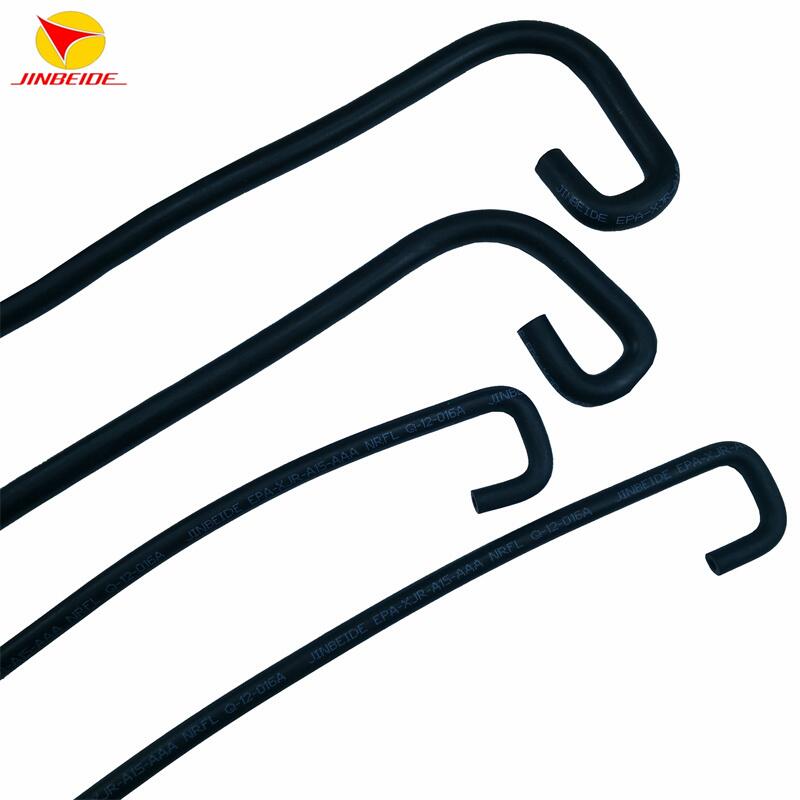

Marine Engines EPA &CARB Certified Low Permeation Fuel Line

| Product: | Marine Engines EPA &CARB Certified Low Permeation Fuel Line |

| Item No.: | JBD-A009 |

| Size & Shape: | ID≥Φ2.5 mm; Customized as Required. |

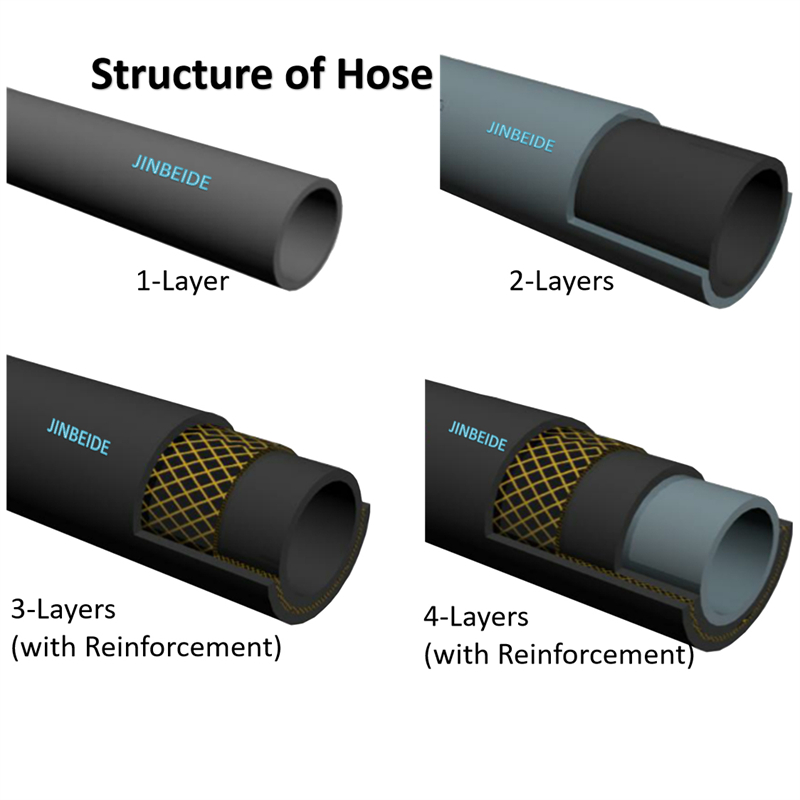

| Material: | FKM; FKM/ECO; FKM/ECO/AR/ECO |

| Structure: | 1 to 4-layers |

| Color: | Black |

| Application | Use for Marine Engines,Outboard Engines & Inboard Engines |

| EPA & CARB CERTIFICATE | YES. |

| Standard | SAE, SAE J1527,USCG,ISO7840, ASTM and so on |

| Shipping Port | Xiamen |

| OEM/ODM | Accepted |

| Package | PE bag+Carton+Pallet |

| Payment Terms | T/T, L/C,Western Union |

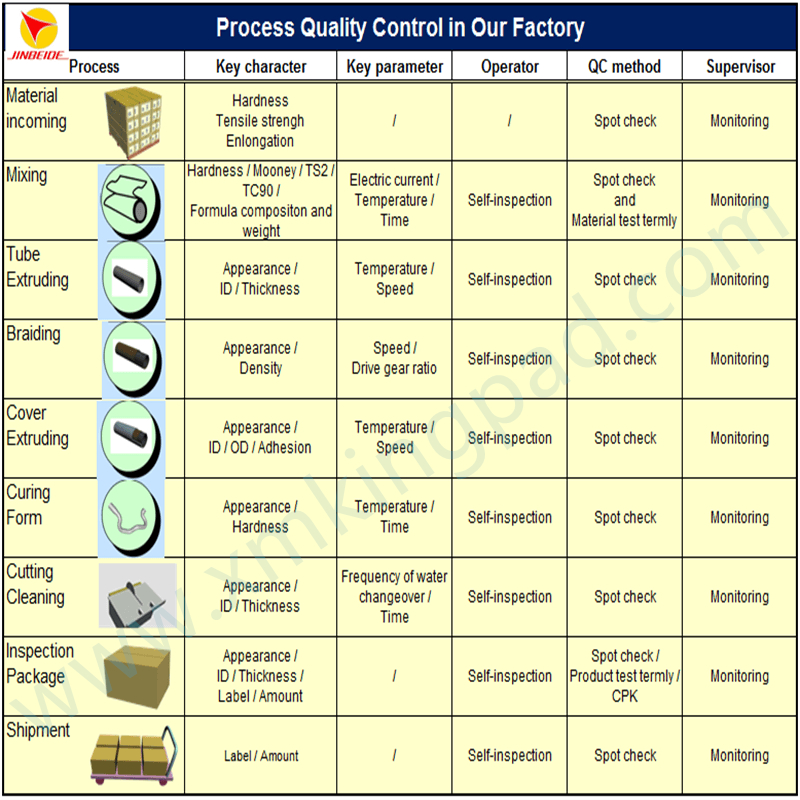

| Factory | ISO/IATF16949 registered |

| Technical Teams | 30+ Years experience |

| Sample Leadtime | 7-15 days |

| Production Leadtime | 20-30 days |

SPECIFICATION

| |

|||||

| ADHESION | SEPARATE A 25.4 mm WIDTH | N | 27 MIN | ||

| COLD FLEXIBILITY | 1. HOSE ID≤19.05 MM -20℃±2℃×5h,Flexed 180 degrees ×10 times×0.6MPA PRESSURE |

NO FRACTURE NO CRACKS NO BREAKS | |||

| 2. HOSE ID﹥19.05 MM -20℃±2℃×5h IN UNRESTRMED LOOP.two jaws 50.8mm~63.5mm |

NO FRACTURE NO CRACKS NO BREAKS | ||||

| VACUUM COLLAPSE | 65.7kpa×(15s~60s) | <20% | |||

| BURST TEST | HOSE ID <25.4 MM | 1.2MPA(175PSI) MIN | |||

| HOSE ID >25.4 MM | 0.62MPA(90PSI) MIN | ||||

| FUELE RESISTANCE AND FUEL PERMEATION | 23℃±2℃×48h | TENSILE CHANGE | % | -40 MAX | |

| ELONGATION CHANGE |

% | -40 MAX | |||

| VOLUME CHANGE | % | 0~+50 | |||

| PERMEATION | 15g/m2/24h MAX | ||||

| FLAMMABILITY | A BUNSEN BURNER SHALL BE USED TO START BURNING OF THE STRIPS NUTIL APPROXFMATELY 12.7 MM OF THE STRIP IS BURNING VIGOROUSLY. | THE FLAME SHALL BE SELF-EXTINGUISHING WITHIN 60S | |||

| FIRE RESISTANCE | ACCORDING TO SAE J1527 5.1-5.4 | NO LEAKAGE | |||

OEM & ODM

Marine Engines EPA &CARB Certified Low Permeation Fuel Line can be OEM & OEM as per client's drawings ,samples and other requirements, meeting the Low Permeation requirement according to the Standard of SAE J1527,USCG,ISO 7840, ASTM, SAE,YDK,HES, EX-S and so on.

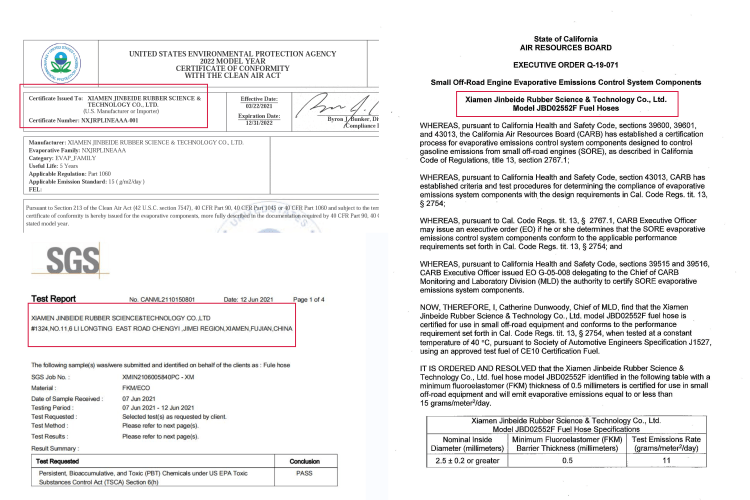

EPA & CARB CERTIFICATE

Marine Engines EPA &CARB Certified Low Permeation Fuel Line achieved the EPA & CARB Certificate.

APPLICATION

Marine Engines EPA &CARB Certified Low Permeation Fuel Line use for Marine Engines, Outboard Engines & Inboard Engines.

Our Uniquie Advantages:

A: 30+ Years Experienced Professional Technical Teams with strong R&D Center.

B: Powerful Capacity with 4 Factories Production Base.

C: Stable Quality and Competitive Price----We are an integrated company combining Rubber Raw Materials Refining & Mixer Process and manufacturing Rubber products with professional Technics, as well as Rubber Raw Materials Wholesales.

D: Delivery time----20-30 days for mass production.

Yes, OEM/ODM can be acceptable.

Most of our products are customized and manufactured as per client’s Drawings and Requirements.

Yes, PPAP’s is a basic documents under our IATF16949 certificate.

T/T and L/C is acceptable . 30% downpayment and balance before shipments by T/T. Or 100% irrevocable LC at sight.

Our main Rubber & Plastic materials are NBR,SBR,NR,ACM,AEM,CSM,ECO,FKM,VMQ, EPDM,SILICONE,PVC,TPU,ect.

Structure of Hose

Process Of Quality Control

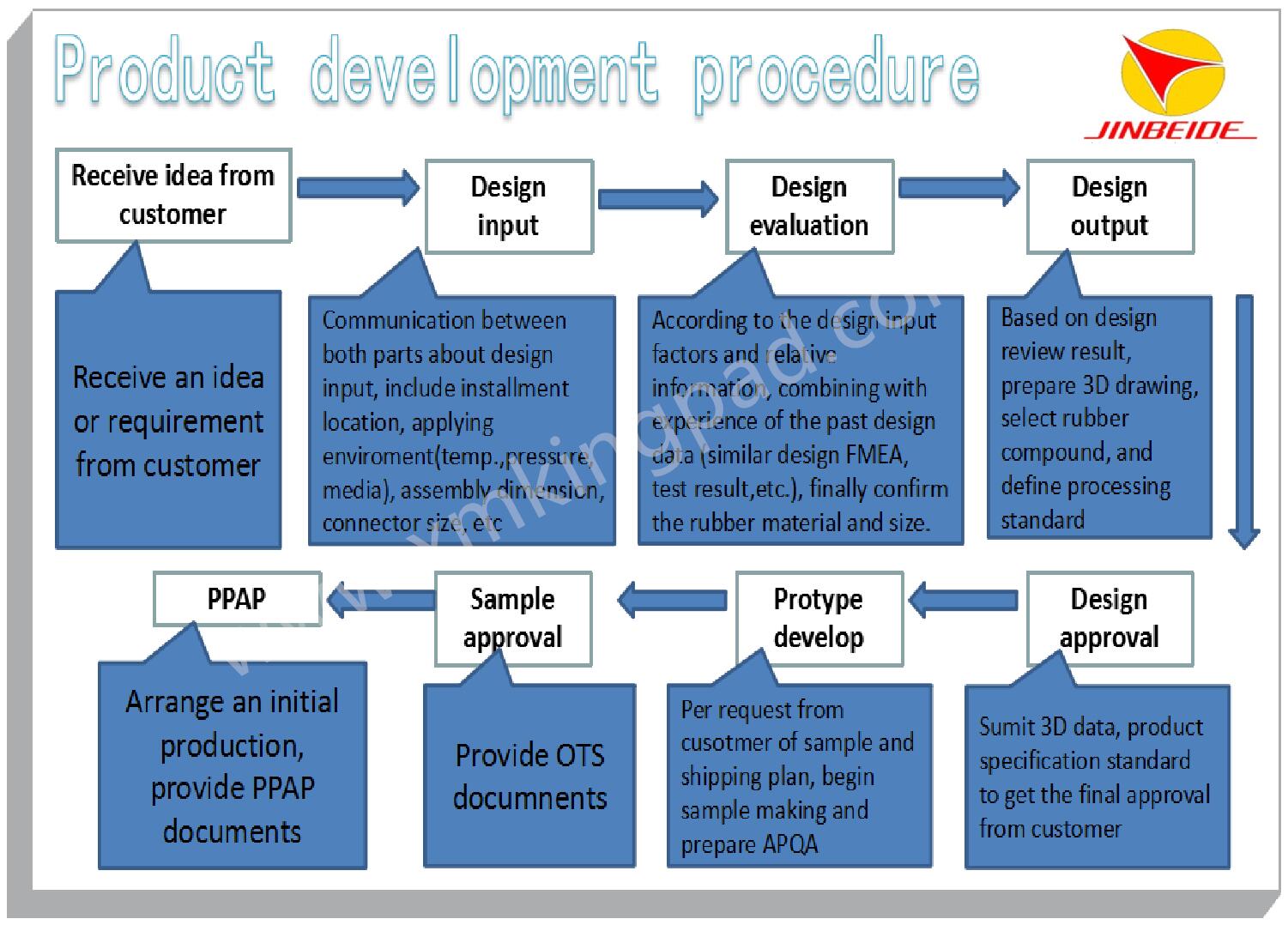

Process of Product Development

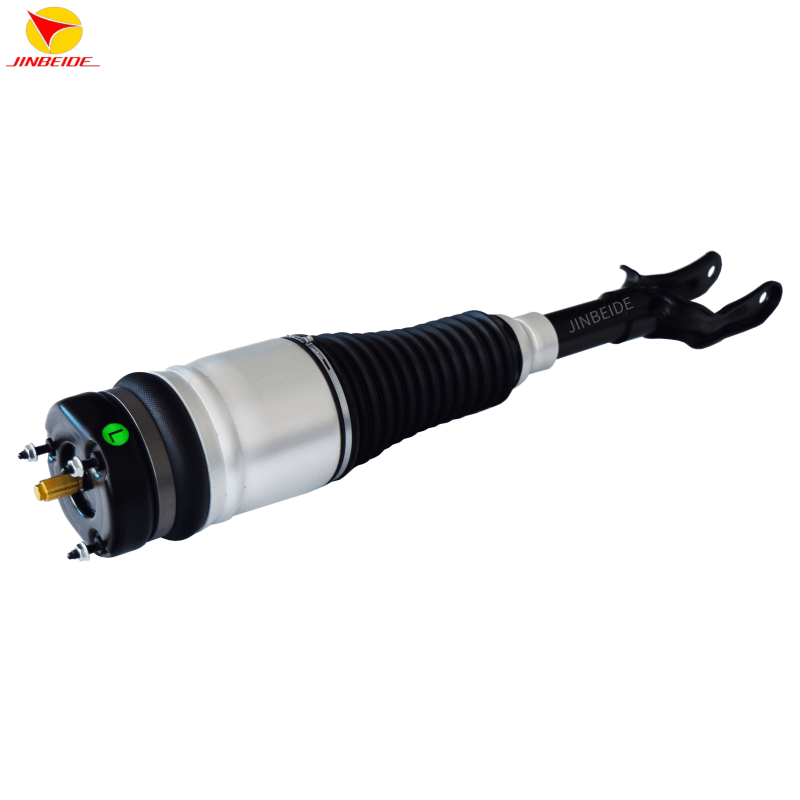

Products Collect

Packaging & Shipping

| |

|||||

| ADHESION | SEPARATE A 25.4 mm WIDTH | N | 27 MIN | ||

| COLD FLEXIBILITY | 1. HOSE ID≤19.05 MM -20℃±2℃×5h,Flexed 180 degrees ×10 times×0.6MPA PRESSURE |

NO FRACTURE NO CRACKS NO BREAKS | |||

| 2. HOSE ID﹥19.05 MM -20℃±2℃×5h IN UNRESTRMED LOOP.two jaws 50.8mm~63.5mm |

NO FRACTURE NO CRACKS NO BREAKS | ||||

| VACUUM COLLAPSE | 65.7kpa×(15s~60s) | <20% | |||

| BURST TEST | HOSE ID <25.4 MM | 1.2MPA(175PSI) MIN | |||

| HOSE ID >25.4 MM | 0.62MPA(90PSI) MIN | ||||

| FUELE RESISTANCE AND FUEL PERMEATION | 23℃±2℃×48h | TENSILE CHANGE | % | -40 MAX | |

| ELONGATION CHANGE |

% | -40 MAX | |||

| VOLUME CHANGE | % | 0~+50 | |||

| PERMEATION | 15g/m2/24h MAX | ||||

| FLAMMABILITY | A BUNSEN BURNER SHALL BE USED TO START BURNING OF THE STRIPS NUTIL APPROXFMATELY 12.7 MM OF THE STRIP IS BURNING VIGOROUSLY. | THE FLAME SHALL BE SELF-EXTINGUISHING WITHIN 60S | |||

| FIRE RESISTANCE | ACCORDING TO SAE J1527 5.1-5.4 | NO LEAKAGE | |||