Customized NBR Rubber Automotive Fuel Supply System Intake Hose

| Product: | Customized NBR Rubber Automotive Fuel Supply System Intake Hose |

| Item No.: | JBD-E008 |

| Size & Shape: | ID≥Φ2.5 mm; Customized as Required. |

| Material: | NBR+PVC

NBR/YARN/NBR+PVC |

| Color: | Black |

| Application | Use for Fuel Supply System in Automobiles,Motorcycles.ATV,Garden Machinery,Engines,Generators and so on |

| Standard | SAE, YDK,HES, EX-S,ASTM and so on |

| Shipping Port | Xiamen |

| OEM/ODM | Accepted |

| Package | PE bag+Carton+Pallet |

| Payment Terms | T/T, L/C,Western Union |

| Factory | ISO/IATF16949 registered |

| Technical Teams | 30+ Years experience |

| Sample Leadtime | 7-15 days |

| Production Leadtime | 20-30 days |

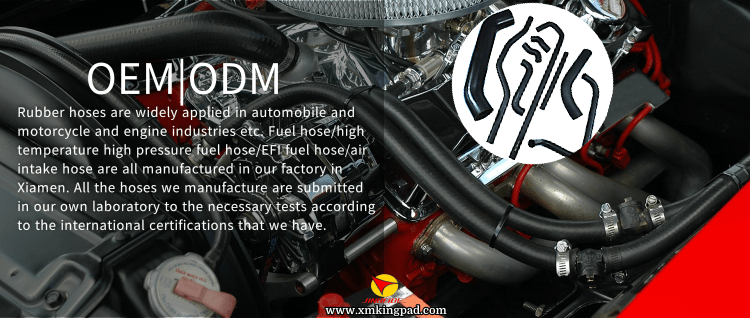

OEM & ODM

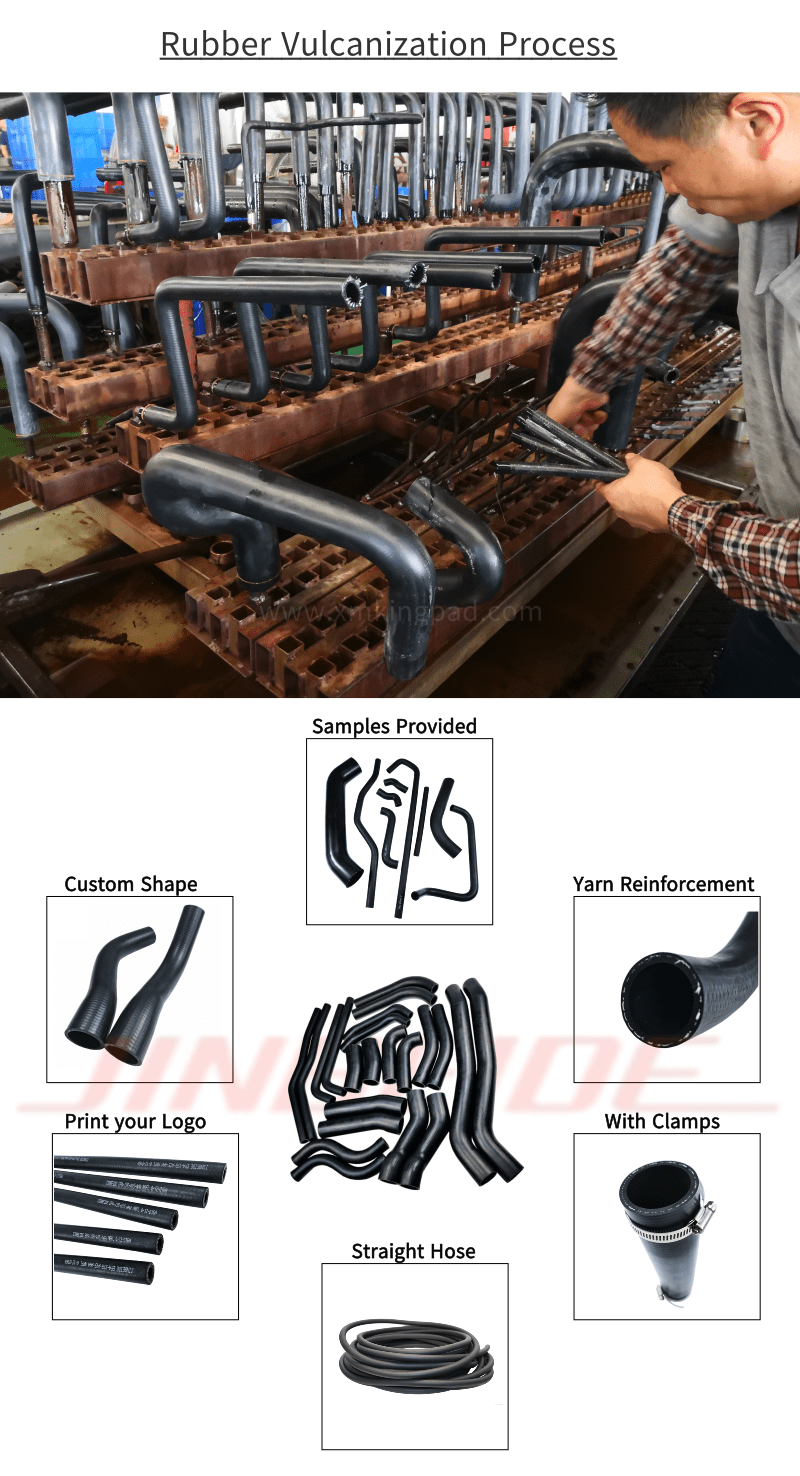

Customized NBR Rubber Automotive Fuel Supply System Intake Hose can be accepted OEM & OEM as per client’s drawings ,samples and other specifications,are widely applied in automobile and motocycle and engine industries ect, Fuel Hose, High Temperature & High Pressure Fuel Hose, EFI Fuel Hose, Air Intake Hose are all manufactured in our factory. All the hoses we manufactured are submitted in our laboratory to the necessary tests and meet the Standard of SAE, YDK,HES, EX-S,ASTM and so on,

The Main materials are FKM/ECO; FKM/ECO/YARN/ECO; ACM/YARN/ACM;NBR/YARN/CSM;NBR/YARN/NBR+PVC;NBR+PVC;NBR+CSM/CM;

NBR,NR,ECO,ECO/CSM. and so on.

APPLICATION

Customized NBR Rubber Automotive Fuel Supply System Intake Hose widely Use for Fuel Supply System, Transmission System, Power Steering System, Brake System, Air Intake system in Automobiles, Motorcycles, ATV, Garden Machinery, Engines, Generators and so on.

SPECIFICATION:

| RUBBER TEST METHODS & SPECIFICATIONS | |||||

| EXTRACTABLES | ASTM FULE C,300MM LONG SPECIMENS METHODS CONFORM TO 6.5.8 |

g/m2 | 7.75 MAX | ||

| PERMEATION | ASTM FULE C, METHODS CONFORM TO 9.1~9.2 |

g/m2/24H | 600 MAX | ||

| BURST | HOSE ID < 9.53mm | MPA | 1.72 MIN | ||

| HOSE ID 9.53mm~25.4mm | MPA | 1.20 MIN | |||

| HOSE ID > 25.4mm | MPA | 0.55 MIN | |||

| VACUUM COLLAPSE | DURING APPLICATION OF VACUUM FOR A MINIMUM OF 15S AND NOT MORE THAN 60S | % | 20 MAX | ||

| COLD FLEXIBILITY | -34℃×5H,AFTER CONDITIONING ASTM D380 AND WHILE STILL IN THE COLD CHAMBER,THE JAWS SHALL BE BROUGHT TOGETHER AS RAPIDLY AS POSSIBLE UNTIL THEY ARE 25.4MM APART.B16 | NOT FRACTURE, NO CRACKS, NOCHEKS, NO BREAKS |

|||

| OZONE RESISTANCE | SPECIMEN:12.7MM×100MM,AROUND A 12.7MM DIAMETER MANDREL,100MPA±5×40℃×70H | NO CRACKS | |||

| ADHESION | SEPARATE A 25.4MM WIDTH | N | 27 MIN | ||

| KINK RESISTANCE | 300MM LONG SPECIMEN,23℃×2H,BEND HOSE ALONG ITS NATURAL CURVATURE AND INSERT THE OTHER END CAREFULLY INTO THE SECOND HOLE UNTIL IT PROJECTS 63 MM OUT THE OTHER SIDE | PASS | |||

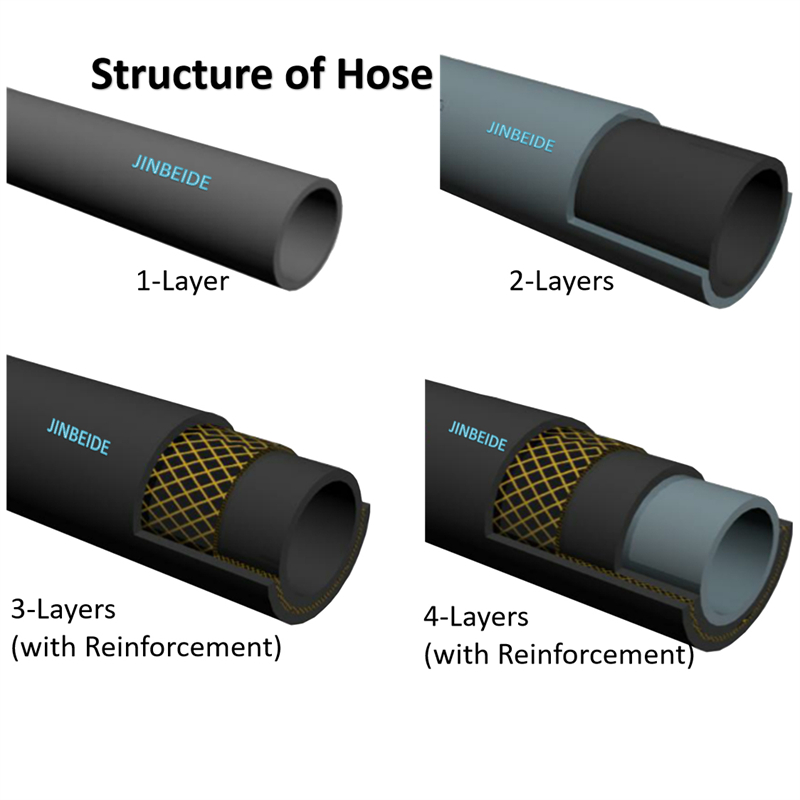

Structure of Hose