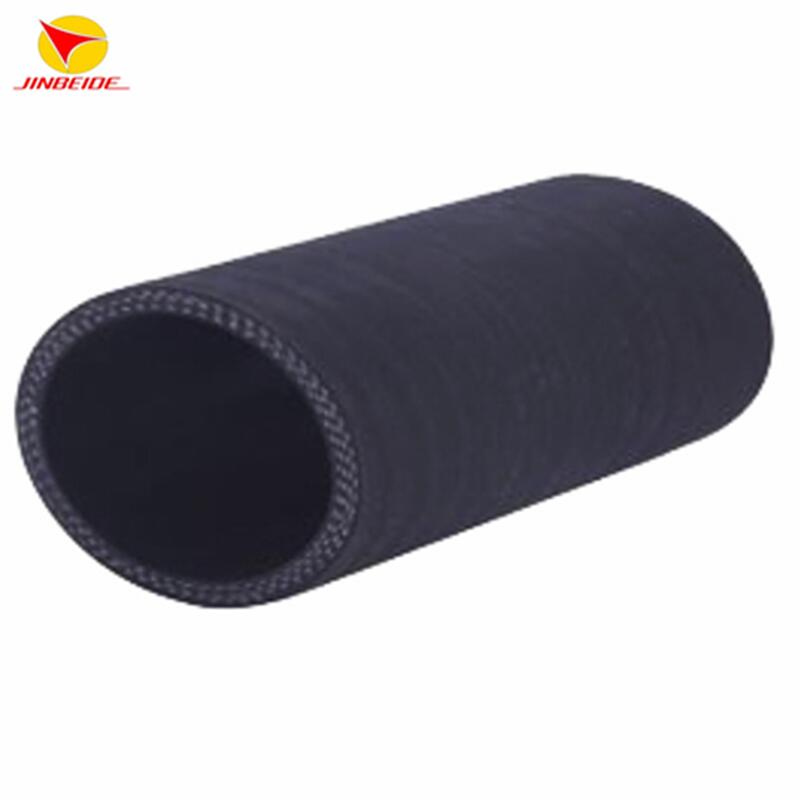

Customized Rubber Braided Fuel Filter Inlet Hose with Hose Clamps

| Product: | Customized Rubber Braided Fuel Filter Inlet Hose with Hose Clamps |

| Item No.: | JBD-E020 |

| Size & Shape: | ID≥Φ2.5 mm; Customized as Required. |

| Material: | NBR/YARN/NBR+PVC

NBR+PVC/YARN/CSM FKM/ECO/YARN/ECO |

| Color: | Black |

| Application | Use for Fuel Supply system in Automobiles,Trucks, Motorcycles.ATV,Garden Machinery,Engines,Generators and so on |

| Standard | SAE, YDK,HES, EX-S,ASTM and so on |

| Shipping Port | Xiamen |

| OEM/ODM | Accepted |

| Package | PE bag+Carton+Pallet |

| Payment Terms | T/T, L/C,Western Union |

| Factory | ISO/IATF16949 registered |

| Technical Teams | 30+ Years experience |

| Sample Leadtime | 7-15 days |

| Production Leadtime | 20-30 days |

OEM & ODM

Customized Rubber Braided Fuel Filter Inlet Hose with Hose Clamps can be accepted OEM & OEM as per client’s drawings ,samples and other specifications,are widely applied in automobile and motocycle and engine ect, Fuel Hose, High Temperature & High Pressure Fuel Hose, EFI Fuel Hose re all manufactured in our factory. All the hoses we manufactured are submitted in our laboratory to the necessary tests and meet the Standard of SAE, YDK,HES, EX-S,ASTM and so on,

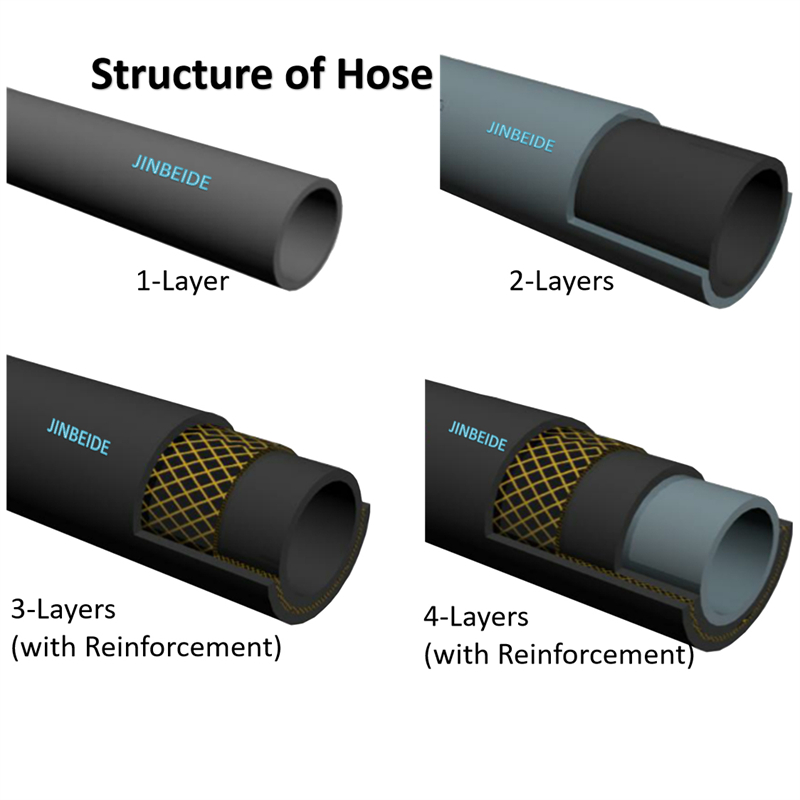

The Main Adopted materials are FKM/ECO; FKM/ECO/YARN/ECO; ACM/YARN/ACM;NBR/YARN/CSM;NBR/YARN/NBR+PVC;NBR+PVC;NBR+CSM/CM; NBR,NR,ECO,ECO/CSM. and so on.

SPECIFICATION

| Test Condition and Result | ||||||||||

| NO | Item | Test Condition | Basic Value | Test Value | Judge | |||||

| 1 | Burst test | Test burst pressure | ≥6.2MPa | 7MPa | OK | |||||

| 2 | Vacuum Collapse Test | 一81KPa ,15-60 seconds | OD Changing Rate,Max:-20% | -6.5% | OK | |||||

| 3 | Col Flexibility | A)、To be dry heat aged for 135℃×70Hrs,after aging,to be conditioned at -40℃×5Hrs | Fixed in the cold chamber through 180 degrees from the the centerline to a diameter of 10 times the Max OD of the hose | NOT FRACTURE, NO CRACKS, NOCHEKS, NO BREAKS |

OK | |||||

| Burst pressure ≥0.69MPa | 0.81MPa | OK | ||||||||

| B)、To be immersed in ASTM Oil No. 3 for 135℃×70H,then to be conditioned at -40℃×5Hrs | Fixed in the cold chamber through 180 degrees from the the centerline to a diameter of 10 times the Max OD of the hose | NOT FRACTURE, NO CRACKS, NOCHEKS, NO BREAKS |

OK | |||||||

| Burst pressure≥0.69MPa | 0.76MPa | OK | ||||||||

| 4 | Tensile Strength | Outer Layer ≥8MPa Midium/Inner Layer ≥5MPa |

Outer:10MPa Midium:10MPa Inner:9MPa |

OK | ||||||

| Elongation | Outer Layer ≥150% Mid/Inner Layer ≥125% |

Outer:259% Midium:296% Inner:276% |

OK | |||||||

| 5 | Dry Heat Resistance | Ater 150℃*7days being aged, Slowly straighten | Surface without cracking and carbonization | No cracking and carbonization | OK | |||||

| 6 | FUEL RESISTANCE | To be immersed in FUEL C RT*48Hr | Inner Layer:rate of volume change ≤+10% | 7% | OK | |||||

| 7 | OIL RESISTANCE | 试To be immersed in ASTM Oil 3#150℃*7Hrs | Outer Layer:Change rate of tensile strength ≤+100% | 55% | OK | |||||

| 9 | OZONE RESISTANCE | SHALL BE ACCORDANCE WITH ASTM D 1149, THE SPECIMEN SHALL BE ALLOWED TO REST IN AN OZONE-FREE FOR 23℃×24H ,AND THE MOUNTED SPECIMEN SHALL BE PLACED IN A TEST CHAMBER CONTAINING OZONE AT 100MPA×40℃,AFTER 70Hrs OF EXPOSURE | NO CRACKS (BE VISUALLY INSPECTED UNDER 7X MAGNIFICATION) |

No Cracks | OK | |||||

APPLICATION

Customized Rubber Braided Fuel Filter Inlet Hose with Hose Clamps widely Use for Fuel Supply System, Transmission System, Power Steering System, Brake System, Air Intake system in Automobiles, Trucks, Motorcycles, ATV, Garden Machinery, Engines, Generators and so on. In order to be convenient to assembly with parts, we also supply the Hose Clamps on the both end of hose.

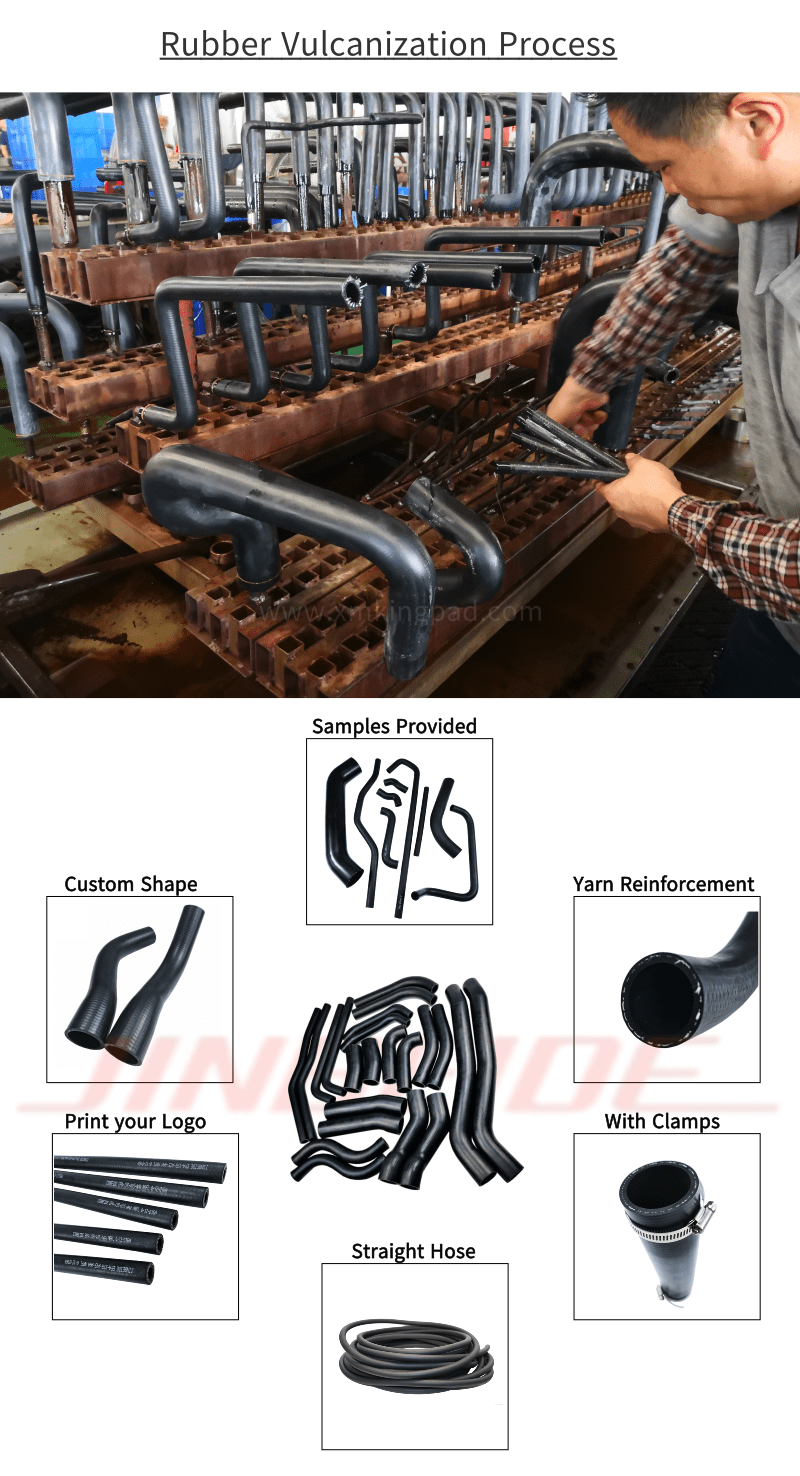

Our Uniquie Advantages:

A: 30+ Years Experienced Professional Technical Teams with strong R&D Center.

B: Powerful Capacity with 4 Factories Production Base.

C: Stable Quality and Competitive Price—-We are an integrated company combining Rubber Raw Materials Refining & Mixer Process and manufacturing Rubber products with professional Technics, as well as Rubber Raw Materials Wholesales.

D: Delivery time—-20-30 days for mass production.

Yes, OEM/ODM can be acceptable.

Most of our products are customized and manufactured as per client’s Drawings and Requirements.

Yes, PPAP’s is a basic documents under our IATF16949 certificate.