In order to meet the requirement of Low Oil Permeation under the CARB and EPA regulation in American markets, the FKM is widely used in manufacturing the CARB and EPA compliant Low Permeation Fuel Line Hose in application of ATV, Motorcycles,Generators,Off-Road Engines, Marine Engines, Garden Machinery, Outdoor Power Equipments, ect.

First, the classification of Fluoro Rubber (FKM )

Fluoro rubber 26: Vinylidene fluoride - hexafluoropropylene, Viton A, No. 2 fluororubber

Fluororubber 246: Vinylidene fluoride - tetrafluoroethylene - hexafluoropropylene, Viton B, No. 3 fluoro rubber

Fluoro rubber 23: Vinylidene fluoride - trifluorochloropropylene, no. 1 fluororubber

Vinylidene fluoride rubber: Vinylidene fluoride - tetrafluoroethylene -PMVE- sulfide point monomer, Viton GLT

Perfluoroether rubber: Tetrafluoroethylene -PMVE- perfluorosulfide point monomer, Kalrez

Tetrafluoroethylene - hydrocarbon propylene, Aflas

Fluorine and silicone rubber

Phosphone-nitrile fluororubber

Nitrofluoro rubber

Second, FKM processing important factors

Mooney viscosity, curing speed, coke safety, fluidity, demoulding

Third, FMK common processing technology

1. Injection molding: the use of this process of fluorine rubber can use low Mooney viscosity and medium Mooney viscosity (20-60mV), good coke safety and vulcanization speed brand.

2), Injection Pressure: the use of this process of fluorine rubber can use low Mooney viscosity and medium Mooney viscosity (20-60mV), good burning safety brand, so as not to produce coke in the process of injection.

3. plate molding: the use of this process of fluorine rubber can use high Mooney viscosity (50-90MV), vulcanization speed brand.

4. extrusion molding: using this process of fluorine rubber can use low Mooney viscosity (20-40MV), good coke safety brand. Processing AIDS can be used in many situations to improve fluidity and surface finish.

5. coating molding: the viscosity of the solution is determined by the selected solvent and filler amount. The stability (storage life) of the solution is the first problem to be considered.

-- Two-stage vulcanization: Rubber is finally vulcanized in two stages for optimum performance. The general two-stage vulcanization condition is 230℃ @ 24h. However, the time and temperature of the second stage vulcanization varies with the product, process and cost. For some applications. Two stage vulcanization may be dispensed with.

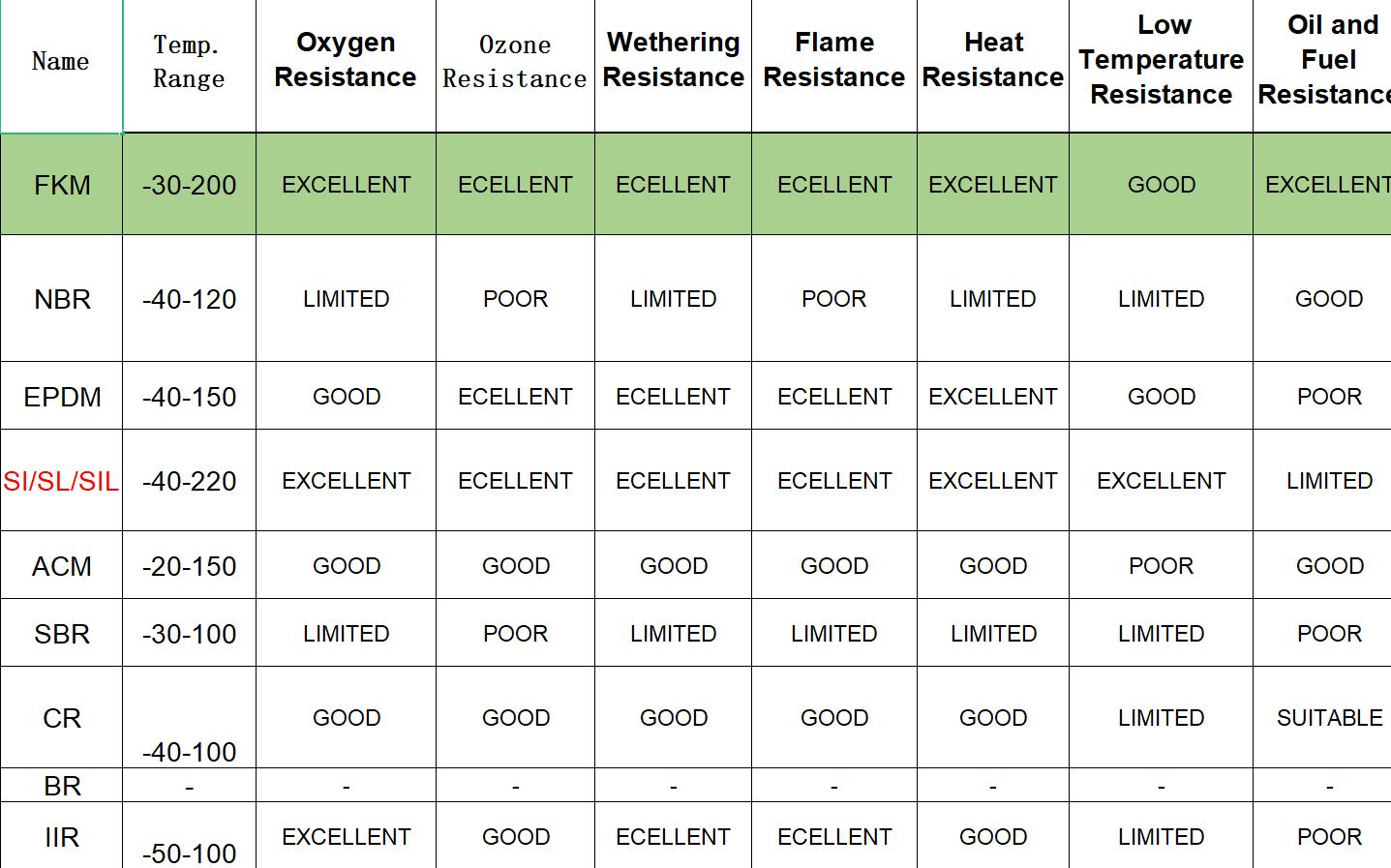

Four, Advantage of Different Rubber

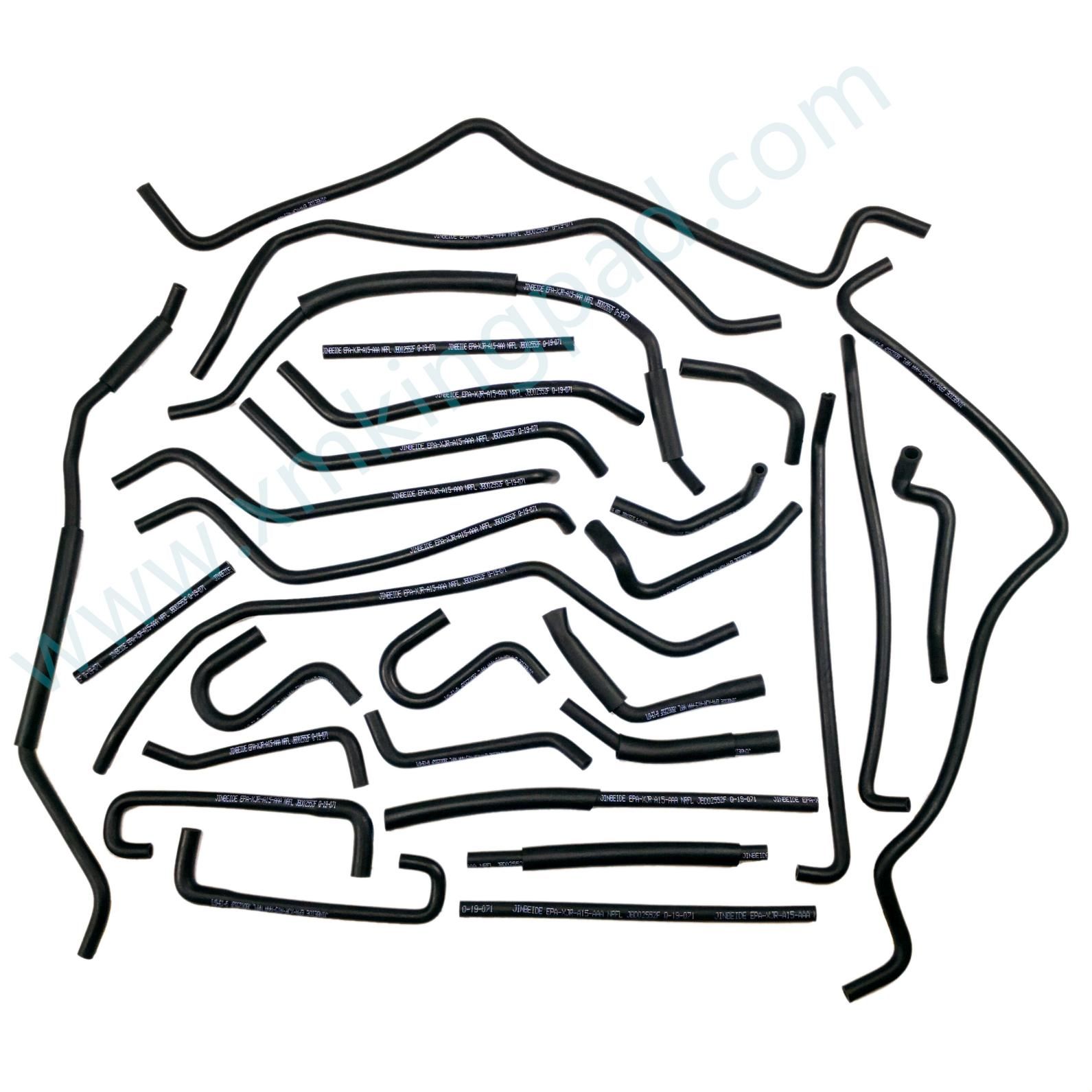

Different Shape of CARB & EPA Fuel Line Hose

Different Shape of CARB & EPA Fuel Line Hose

Five, the application of FKM

Automotive, aerospace, petrochemical and machinery industries are the most widely used fluororubber fields, and 60% ~ 70% of fluoro rubber used in the automotive industry.

Relevant regulations for automobiles will have a profound impact on the application of fluororubber. The biggest challenge for the fluoroelastomer production industry is to help the automotive industry find better and lower permeability materials to meet stringent new automotive emission standards. Fuel system and Engine manufacturers have long focused on fluoroelastomers for fuel and driveline such as Fuel Hoses, Fuel Line, Engine intakes and oil-resistant Hose, EPA & CARB Certificated Fuel Line/Fuel Hose, Low Permeation(≦2.5g/m2/day) Fuel Line/Fuel Hose use in ATV, Motorcycles,Generators,Off-Road Engines, Marine Engines, Garden Machinery, Outdoor Power Equipments, Automobiles.ect.

Post time: Nov-19-2021